The Myerscough College Ag Net Zero Challenge – Flavourfresh

Land management is amongst the largest contributors to climate change and there is an urgency for agriculture to transform from being a net emitter of carbon (CO2e) to a net sequester of carbon (CO2).

Carbon Farm Audit #7

Courtesy of David Yeates

The Myerscough College Ag Net Zero Challenge is part of The Lancashire Colleges’ Strategic Development Fund Pilot, supporting colleges and local employers to work together to create a skilled workforce for a future low-zero carbon economy.

Farm Profile

David Yeates from Flavourfresh in Banks, Lancashire, volunteered to participate in the Myerscough College Ag Net-Zero Challenge. They undertook a whole farm carbon audit to identify areas of improvement within their farm business to reduce carbon emissions.

Flavourfresh Salads

Banks

Southport

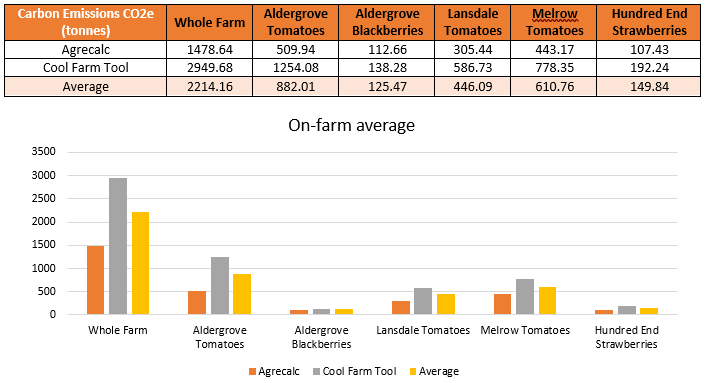

tHE CARBON AUDIT

A carbon audit is an assessment of the emissions of carbon dioxide equivalents (CO2e) produced by each enterprise within a business and, where possible, looks at the sources of sequestration within the business. The carbon audit at Flavourfresh was carried out by Carbon Metrics – a company that specialises in analysing and interpreting existing data and generating a targeted management plan to show how net-zero strategies can be achieved. The farm audit is calculated by using a carbon toolkit. There are currently over 70 toolkits available with no standard industry requirements for data. Therefore, in this case study, we used the average of two carbon audit calculators, Agrecalc and Cool Farm Tool, to produce the results.

Strengths

Good Resource Management. Flavourfresh benefits from good resource management across all four glass house sights. All four sites have a carbon footprint of less than 1kg of CO2e per kg of product. In the future, Flavourfresh should look to ensure that these figures are further reduced with advances in horticultural techniques that enable them to benefit from greater efficiencies. Furthermore, Flavourfresh already utilises several precision techniques such as drip-fertilising and 24hr lighting to enhance the growth rates of plants.

Low Fertiliser Usage. Due to precision application techniques used in the glasshouses, Flavourfresh benefits from low fertiliser usage across the four sites. By maximising nutrient uptake through solution drip feeding, the business is maximising its efficiency and profitability, considering recent jumps in fertiliser price. Furthermore, the strategic application prevents leaching from excess fertiliser application and the release of trace gases such as Nitrous Oxide.

Areas for Consideration

Renewable Energy Generation. Flavourfresh benefits from using electricity created from four CHP plants across its sites. While these have additional benefits, including CO2 supply to the glasshouses and heat maximizing crop growth, these units consume large amounts of fossil fuels. While the CHP’s plants emissions are not included in this audit, it is noticeable that these impact the wider circular economy. Flavourfresh should consider investing in solar panels or wind turbines to install on the margin land around the glasshouses to produce renewable electricity to reduce the site’s dependence on fossil fuels.

Onsite Anaerobic Digesters. Flavourfresh currently exports its used growing packs to an off-sight anaerobic digester and therefore experiences an increase in its carbon footprint due to its transportation. Investing in an onsite anaerobic digester will enable Flavourfresh to benefit from the same by-products as produced from the CHP units.

Carbon Opportunities

Electric Vehicles and Infrastructure. Some progress is being made across the four sites at Flavourfresh to introduce electric vehicles. This good work needs to be continued with widespread ambitions, looking at changing the company’s lorries to electric alternatives. Furthermore, Flavourfresh should move away from using petrol-powered horticultural equipment and move to battery-powered technologies to reduce their consumption of fossil fuels.

Growth Intensification. Flavourfresh should expand its usage of LED lighting across its four sites. Using LED lighting, Flavourfresh benefits from the growth intensification of plants, as there will be longer periods in which the plants can photosynthesise and grow. Furthermore, expanding the LED lighting coverage across all four sites will enable Flavourfresh to reduce the time when the glasshouses fallow between crops, as the lack of sunlight in winter will no longer be an inhibitor for growth.

Benefits for the Business

Improved return on investment. By following the areas of consideration and the mitigation measures, the farm can expect to see a better return on crop costs and fuel usage. It will also see the amount of CO2e emitted fall further, helping to achieve Net-Zero. The farm could look to invest in renewables, but this would only support a small proportion of the way to reach Net Zero, and further work on fuel and fertiliser needs to be carried out to significantly reduce the farm’s carbon output.

Leading the way with Carbon Emissions. Flavourfresh has a real possibility of leading the way in showing how agriculture can help lead the way as part of the path to Net-Zero. As opportunities around low carbon production increase, supply chains will revise their purchasing patterns and prioritise growers aware of their carbon footprint and actively trying to reduce theirs. The excellent resource management across the four sites at Flavourfresh places the company in an enviable position to benefit from its low footprint of CO2e per kg of product in the future.

Innovative Farming Approaches

Flavourfresh makes uses of a number of innovative farming approaches to produce tomatoes and berries across its four farms. At three of the farms, LED lighting is used during the winter months in the glasshouses to maximises productivity of the plants so that they can start to grow earlier in the year, as light will not be a limiting factor.

Furthermore, the farm grows its plants with a hypotonic system and constantly drip feeds the plants liquid fertiliser to ensure that the plants are never lacking vital nutrients for growth of nitrogen, potassium, phosphate, magnesium, or sulphur. The precision nature of the applications means that fertiliser uptake by the plants is high, while further increasing business profitability as minimal excess fertiliser is used across the farms.

Holistic approach to energy usage

At Flavourfresh the farm’s take a holistic approach to energy generation and consumption. The farm uses CHP plants which uses natural gas to produce both electricity for Flavourfresh’s farms, but also produce the co-products of heat and CO2 to be pumped into the glass house to maximise growth rates across the farm.

Excess electricity created from the CHP plants is exported back onto the national grid to ensure that any excess electricity produced is not wasted and therefore results in Flavourfresh from benefitting from cost saving measures.

Subscribe!

Please enter your email below to keep up-to-date with the AG Net-Zero Challenge